Explain the Difference Between Brazing and Soldering

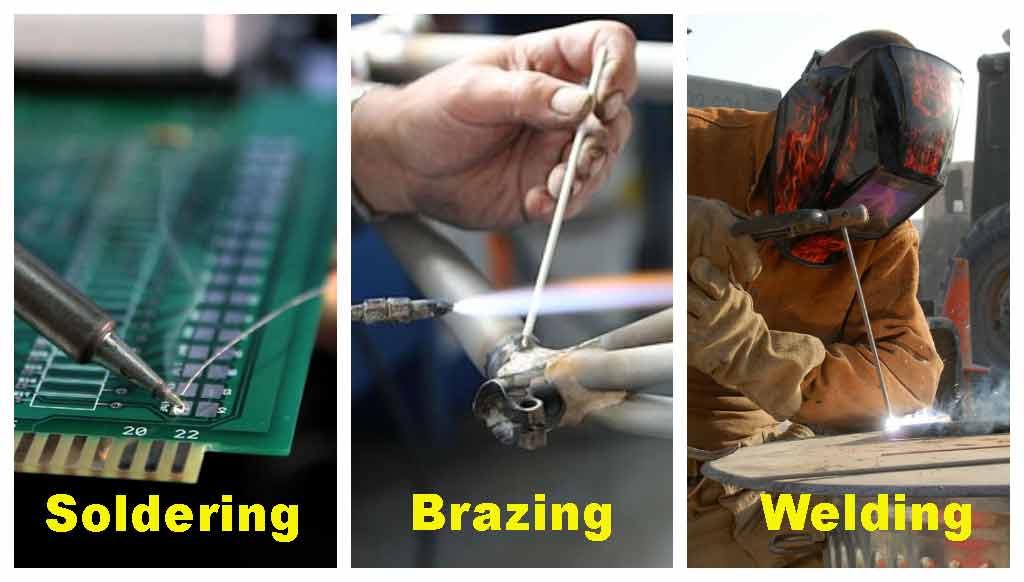

Here is a list of brazing and solderings main differences. Brazing welding and soldering all offer their own strengths and also drawbacks.

The Difference Between Soldering And Brazing With Welding The Definitive Guide Cruxweld

Brazing uses a higher temperature above 450C and soldering uses a temperature below 450C.

. The basic and main difference between soldering and brazing is that soldering is used to make a electrically strong joint between metals which can withstand with all electric loads and brazing is used to make a mechanical strong joint which can withstand with all mechanic loads and stresses. In soldering metal fabricators heat the metal to be bonded but never melt them. Soldering is a cheaper process.

Brazing filler materials are alloys of copper and tin zinc. Now that we know that the main difference between brazing and soldering is the melting point do brazing and soldering have any more distinctions. Soldering and brazing both are mostly used in small industries.

Solder has a liquidus above 450 C. In fact the American Welding Society defines brazing as the process where the filler metal ie. Soldering filler materials are alloys of lead and tin and normally have a melting point of 250 to 300 degree centigrade.

Temperature requirement is up to 450C in soldering joints. Brazing joints are weaker than welding joints but stronger than soldering joints. Temperature required is 3800C in welding joints.

Brazing is used in radiators containers and other tanks pipe fittings heat exchangers. Now the difference is mainly the filler material composition and its melting point. Its best to work with metallurgy experts who can explain the specifics of.

Temperature may go to 600C in brazing joints. The brazing produces stronger joints than soldering. They are both used to join metals.

Soldering brazing and welding are used to join and fill gaps between metal parts. Like welding process but soldering and brazing joining strength is less as compared to welding. 6 rows Brazing is typically used when you are joining two metal pieces that are either dissimilar or have.

Brazing is not easy and a very difficult for automation. This can be used to bear the load up to some extent. Work pieces are heated but below their melting points.

Just as in welding and brazing flux is used to clean metal surfaces so that the solder can flow over the pieces that will be joined. Brazing is quite costly. 8 rows The difference between brazing and soldering is a temperature of 450 degrees centigrade used.

Soldering is a semi-permanent fastener whereas brazing is a permanent fastener. In welding metal fabricators melt the base metal. Explain the difference between brazing and soldering.

Another main difference between soldering and brazing is that brazed joints are significantly stronger than soldered joints. Soldering is most similar to brazing because it uses capillary action to flow the metal into the joint until it cools and hardens. The key difference between these two methods is the heating temperature.

The brazing gives better accuracy and joints may have a good aesthetic appearance. What differentiates soldering and brazing is the melting temperature of the filler metal. Flux is used.

I am often asked about the differences between brazing and soldering. Soldering takes place at a temperature below 840 F Brazing occurs at a temperature above 840 F page 830. Heating of workpieces is not required.

The main difference between welding and soldering is melting. Soldering is used to join two or more metal. The main difference between the two is the temperature.

Preheating of base metal does not require in soldering. There are some similarities between soldering and brazing but many significant metallurgical differences. Each of these joining processes has significance and they are different in terms of base material joining temperature and filler material.

In soldering and brazing a metal alloy solder is melted and flows over the two metals to be joined connecting them together. Soldering is really a very easy and quick process. Perhaps this is a good time to describe the two processes in more detail so that readers can understand the significant differences between them.

Brazing is akin to soldering in that it also uses filler for joining two metals albeit a high-temperature one. Each process has its advantages and disadvantages from a. The best choice depends on your project aims and other factors including budget.

Soldering and Brazing both are joining two or more similar and dissimilar metals. This article covers the difference between soldering vs. Similar to welding brazing creates a mechanical connection between to metal parts.

Explain the difference between brazing and soldering Soldering and brazing differ only in that soldering takes place at a temperature below 840 degrees F 450 C and brazing occurs at a temperature above 840 degrees F 450 C. Definition The only difference is that soldering takes place at temperatures below 840 degrees Fahrenheit and brazing occurs above these temperatures.

7 Main Differences Between Brazing And Soldering Simplified

No comments for "Explain the Difference Between Brazing and Soldering"

Post a Comment